A Few Words

About

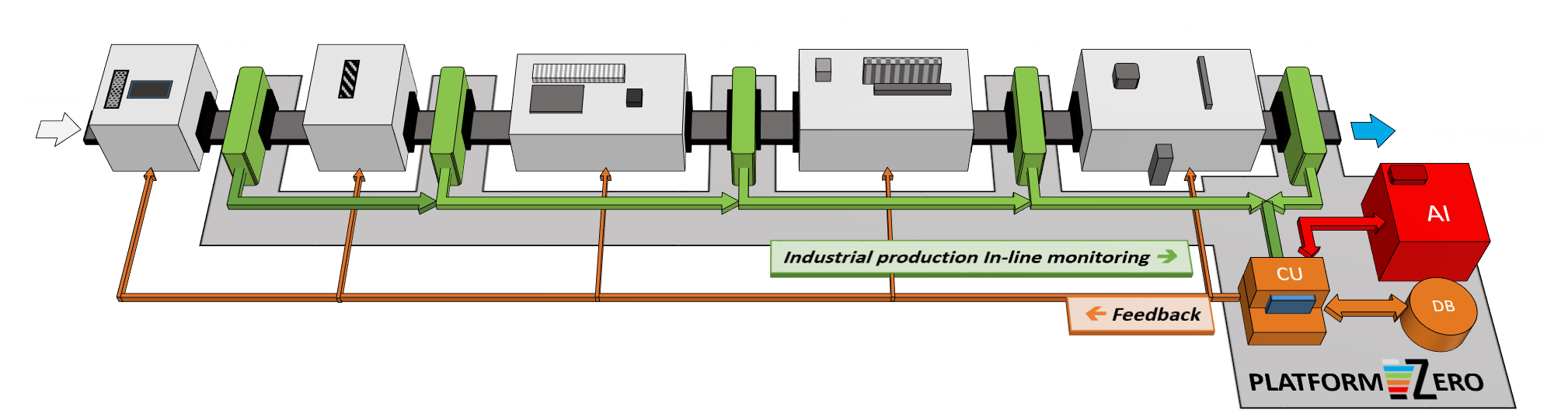

Platform-ZERO

Platform-ZERO kicked-off in January 2023, and within the next four years, this 10M€ innovation project co-funded by the European Commission will contribute to increase the production quality of photovoltaic (PV) devices. The project is targeting to reduce the cost of high-tech PV devices and increase the competitiveness of EU’s PV industry which allows this green technology to become a key energy source for Europe’s transition towards climate-neutral energy generation.