The Platform-ZERO project, co-funded by the European Commission, is driving innovation in photovoltaic (PV) manufacturing by developing advanced in-line process monitoring solutions supported by artificial intelligence. As part of our ongoing dissemination activities, we are excited to share a series of four videos demonstrating the cutting-edge sensor technologies developed by the project partners. Each video illustrates the practical implementation of these sensors, their unique capabilities, and their contribution to improving production quality while reducing costs and waste.

1️⃣ LIBS Sensor

The first video showcases a Laser-Induced Breakdown Spectroscopy (LIBS) sensor operating on the ZSW platform.

By directing a powerful laser at a tiny spot on the material, the sensor generates a spark that emits light containing information about the chemical composition of the sample. Ultra-sensitive detectors capture this light in synchronization with the laser pulse, enabling rapid chemical mapping of materials. Mounted on a motorized stage, the sensor can scan different zones, detecting defects at early production stages and supporting higher-quality PV manufacturing.

2️⃣ Photoluminescence Imaging

The second video features the photoluminescence imaging system, demonstrated at ZSW and Sunplugged and filmed by HZB.

This system employs advanced optical imaging to analyze PV materials and detect defects early in the manufacturing process. By capturing material responses under controlled illumination, the sensor provides critical insights into material quality, helping improve process control and reduce waste.

3️⃣ Multi-Sensor Probe Heads

The third video presents the operation of configurable multi-sensor probe heads developed by IREC for PV material and device characterization.

These probes integrate Raman and photoluminescence spectroscopy at multiple excitation wavelengths, along with VIS–NIR spectral reflectance, allowing non-destructive investigation of layered structures. Installed on an automated testing bench, the system performs synchronized multi-sensor acquisitions and spatial mapping, producing high-quality datasets for AI analytics. This approach enables early detection of process deviations and supports industrial and research process optimization.

4️⃣ Optoelectronic Sensor

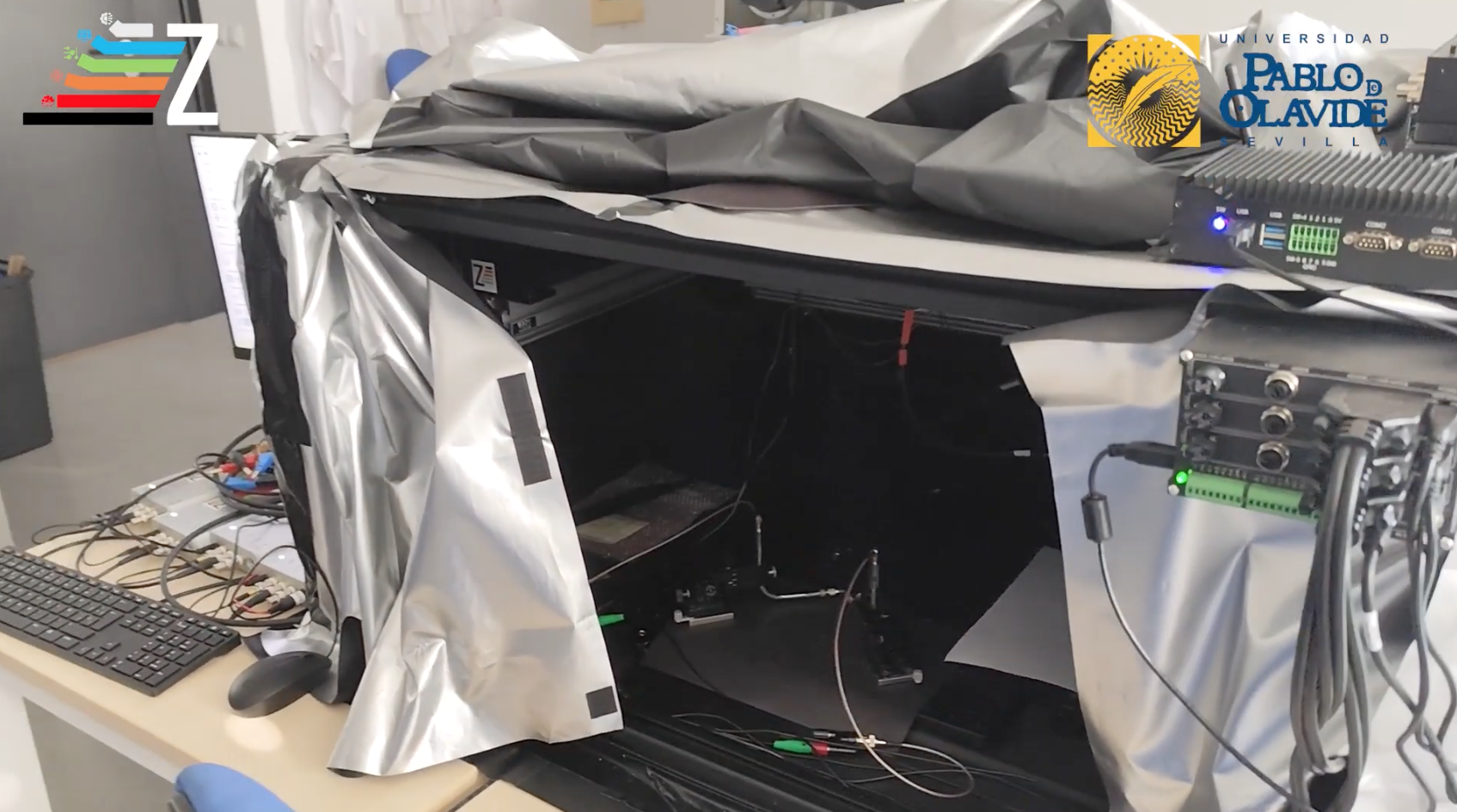

The fourth video highlights an advanced optoelectronic sensor developed by UPO (Universidad Pablo de Olavide).

This compact sensor combines high-speed optical and electronic control in a single device. It performs comprehensive PV cell characterization, including current–voltage measurements, impedance spectroscopy, and external quantum efficiency, while providing high-fidelity datasets for AI-based process monitoring. Designed for integration into manufacturing lines, the sensor ensures that every PV device meets stringent quality standards and supports predictive maintenance.

These four videos illustrate how Platform-ZERO sensors enable real-time, in-line monitoring of PV production processes, providing actionable data to improve efficiency, reduce waste, and support AI-driven process optimization.

Stay tuned for upcoming content as the project continues to advance next-generation technologies for zero-defect photovoltaic manufacturing.